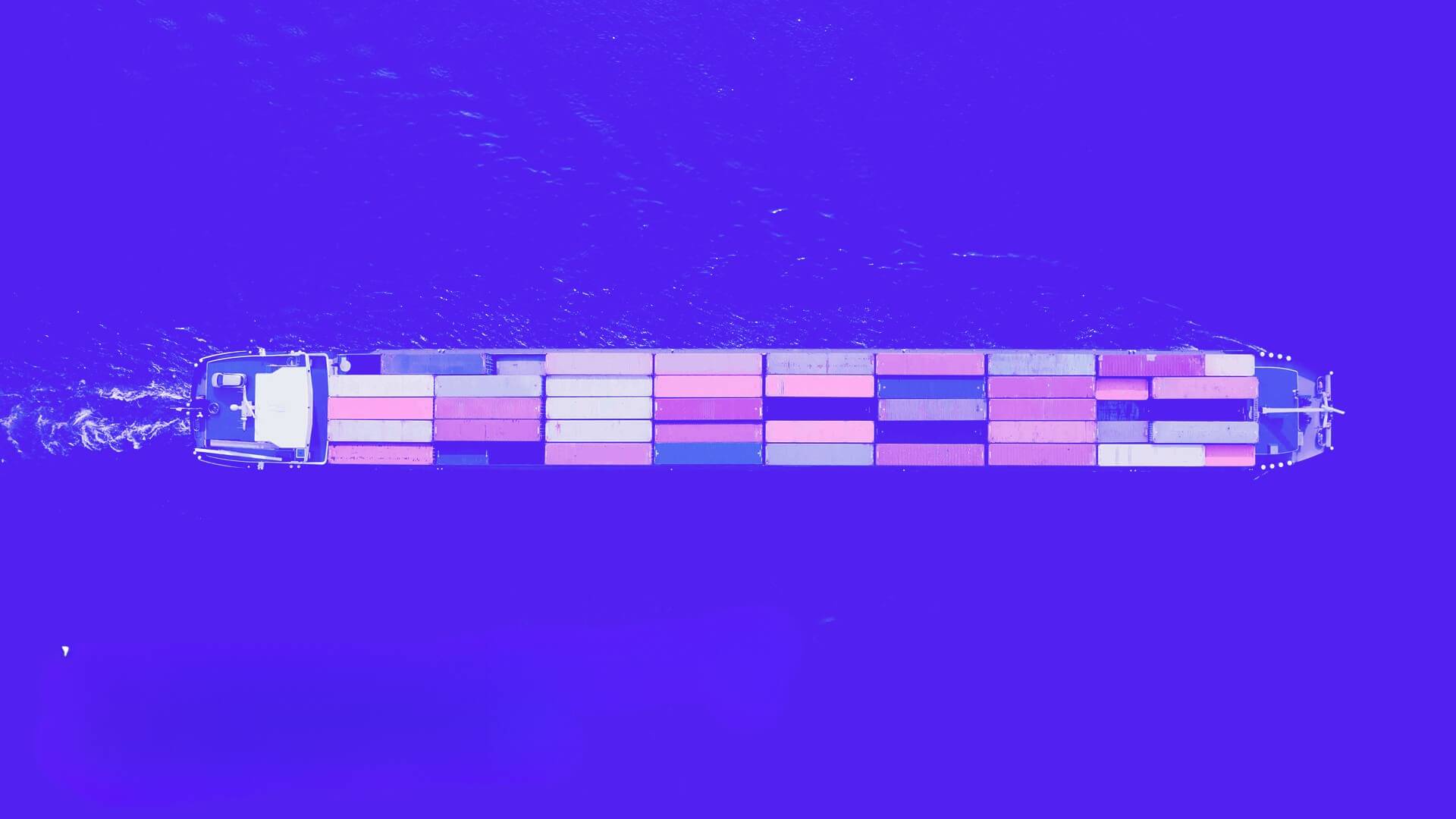

When Hurricane Helene struck North Carolina in 2024, one of General Motors’ suppliers suddenly lost access to water and power. Under ordinary circumstances, this would have triggered an immediate production stoppage. Instead, GM engineers had already anticipated the disruption and intervened in advance, even going so far as to drill a new well. The company’s monitoring system had detected early indicators of infrastructure failure days before the event occurred, according to reporting from Business Insider.

This example illustrates a broader truth: most supply chain disruptions do not arrive without warning. They begin with subtle signals that accumulate over time. The distinction between a temporary setback and a costly shutdown often depends on how early an organization can recognize those signals and how effectively it can act on them.

History shows how costly it can be when foresight is missing. After the earthquake and tsunami that hit Japan in 2011, automakers around the world faced weeks of stalled production because they lacked visibility into their lower-tier suppliers. The shortage of microcontrollers and pigments halted assembly lines from Detroit to Stuttgart. Companies had invested heavily in efficiency, but they had not invested in the ability to anticipate risk. GM’s current predictive approach is, in many ways, a direct response to the vulnerabilities exposed during that period.

Today, GM’s predictive systems are credited with preventing at least 75 factory stoppages in 2025 alone. The tools map supplier networks, monitor local news sources, and flag early indications of instability, whether they involve labor disputes, climate events, or infrastructure concerns. These technologies do not replace human judgment. They simply give managers more lead time to decide how to respond, whether by shifting orders, securing alternate suppliers, or taking operational measures as extreme as drilling a new well. In supply chain management, time is often the most valuable resource.

The scale of the challenge facing global companies remains significant. McKinsey estimates that organizations experience disruptions lasting one to two months approximately every 3.7 years. The economic impact of these interruptions is uneven but consistently heavy, prompting many firms to move predictive systems from experimental pilots to core infrastructure.

Yet predictive insight alone is not enough. Many organizations discover that the difficulty lies not in generating alerts, but in ensuring that the alerts are understood and acted upon. Predictive models can produce thousands of signals, and without thoughtful integration into daily workflows, those signals risk being overlooked. GM’s system succeeds in part because it does not merely surface data; it translates information into actionable context. That capability, turning intelligence into operational clarity, is what differentiates resilience from noise.

This dynamic extends far beyond the automotive sector. A recent McKinsey survey found that while 71% of global companies have adopted AI-based tools for supply chain management, fewer than 20% have managed to scale these tools across their operations. Retailers, energy providers, and manufacturers all face disruptions that may be rare, but whose consequences can be catastrophic when mishandled. The challenge is seldom the sophistication of the model. It is the difficulty of embedding predictive insight into the routines of the people who must ultimately respond.

There are also meaningful limitations. Over-reliance on alerts can create false positives, unnecessary expenditures, or complacency. Smaller suppliers may lack the capacity to respond effectively, even when a warning is accurate. And in regions with limited access to reliable reporting, data gaps can leave critical blind spots. The danger lies in assuming predictive signals are comprehensive when, in fact, they are only approximations of complex conditions.

For firms like Neurony, which develop tailored AI integrations for operational environments, the opportunity lies in making these signals usable. Supply chains do not typically fail because companies lack information. They fail because the right information does not reach the right decision-makers at the right moment. Technology that bridges that gap, quietly, reliably, and consistently, may not attract much attention, but it forms the foundation of genuine operational resilience.

If your organization is exploring how to integrate AI-driven prediction into supply chain operations, Neurony can help you design systems that move beyond alerts and create actionable visibility.

To learn more about building resilient, AI-enabled operational infrastructure, schedule a call now.